Key Points

Our statement

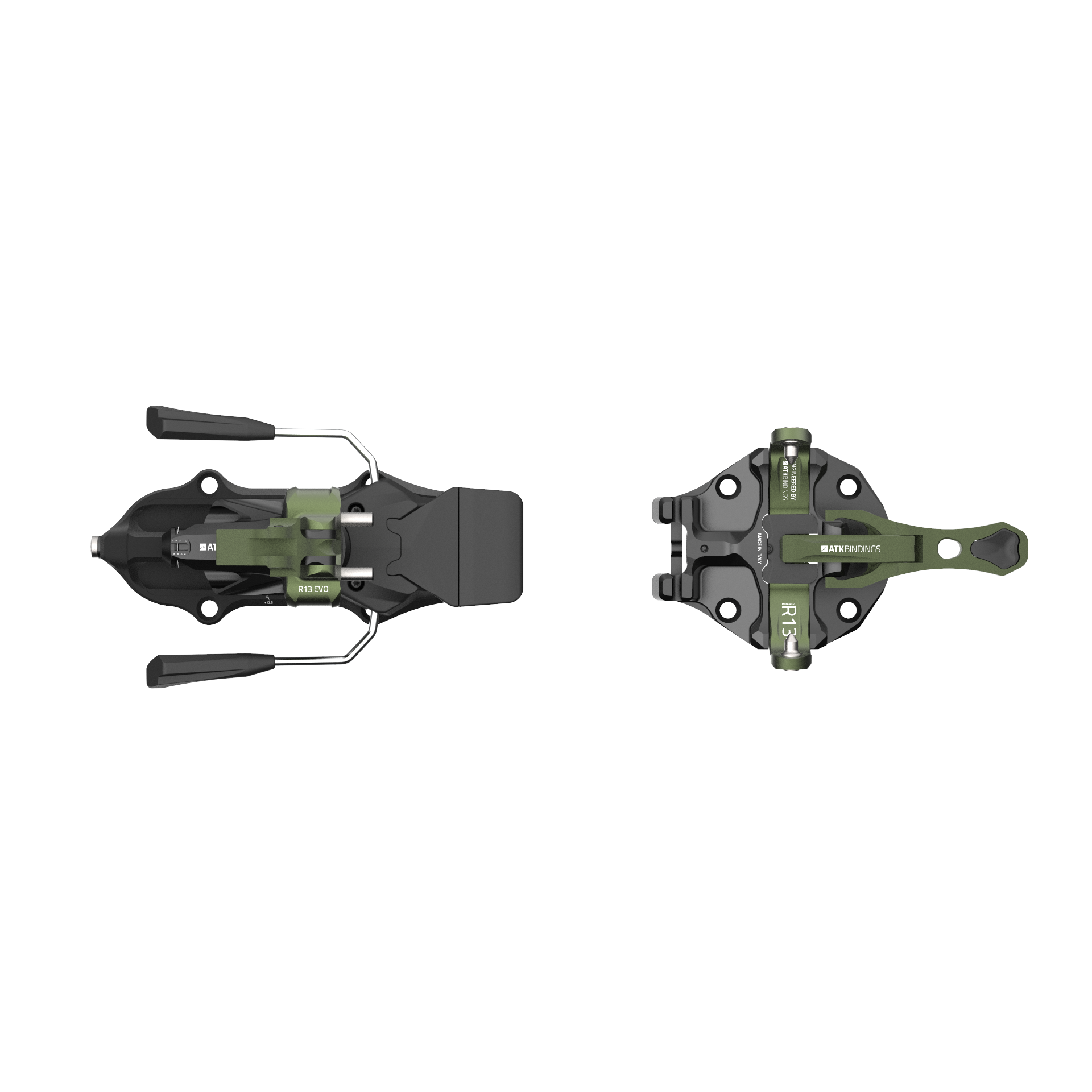

At ATK, our core philosophy centers on achieving utmost lightness in our products. However, it would be a contradiction to provide such light bindings if they come burdened by their weight on the environment. Our goal is to enable every ski mountaineer to relish each step and turn, carrying only the weight of their backpacks on their shoulders!

Current perspective

We at ATK take pride in our Fiorano Modenese headquarters, where our entire production process takes place. Thanks to this setting, we can take incisive action to improve every link in our production chain, from design to packaging. Our state-of-the-art workshop allows us to recycle efficiently, producing products that we then stand by, offering serviceable and replaceable components to extend their lifespan and reduce waste.

Set goals

Our objectives are explicit: achieve carbon neutrality and up to a 70% reduction in carbon footprint by 2025, with our first sustainability report to be completed.

These goals reflect a strong commitment to environmental responsibility and

transparency in their efforts.

Our approach

Embracing

innovation, ATK faces challenges with a focus on lightness and sustainability.

We excel in recycling aluminum shavings, ensuring efficient recovery and reintegration into the raw material market. We also forge networks of consciousness to foster awareness and collaboration in our pursuit of environmentally responsible practices.

Declaration of lightness

Download ATK's Declaration of lightness to follow our steps into the future of our brand and ski mountaineering.

Download our Declaration of lightness

Our commitment for a sustainable future begins at the dawn of our production cycle, where there’s no plastic in sight, just shiny aluminum in many different shapes.

We chose a premium-grade alloy named ERGAL, renowned for its technical qualities. It’s the ideal material for demanding activities like ski mountaineering because it guarantees reliable performances even in challenging conditions. Being easily machinable, it also allows us to engeneer the extremely precise designs we need to help you achieve performance through lightness.

What’s great about Aluminum is that, once recycled, its technical characteristics remain unchanged, so it can still play the leading role in our process!

In order to achieve a wholly sustainable work environment, we are proudly determined not to scatter potential or used resources.

Since we are resolute in not letting useful and clean resources go right over our heads, we paired the solar panels on our roof with an interesting solution to reduce our energy dependency. An ingenious system of mirrors channels sunlight in an optimal way down multiple skylights, lighting up our warehouse and workshop. Less need for electricity and another reason to enjoy a sunny day!

Here at ATK, we also collect and reuse nearly 97% of our machinery lubricants. The ones that we can't keep in our pants are carefully gathered and disposed of in accordance with our local requirements. Additionally, all processed water is recycled, and the only dispersion occurs through evaporation.

As true Aluminum lovers, we don't shudder if it looks like scrapes, because we know that this alloy has a lot to offer even in the shape of machining chips.

That's why we make an effort to collect and recycle 100% of our production scraps. To achieve this we start by thoroughly separating the aluminum chips from all processed water, which we recover to avoid any dispersion. At this point our pure metal scraps are compacted into chunky disks and are ready to be molted at foundry nearby.

The result? A process easier on the environment, that fully takes advantage of the great qualities of the Ergal Aluminum. Once recycled, in fact, this alloy maintains all its technical characteristics and it’s ready to re-enter our production cycle!

Our commitment for a sustainable future begins at the dawn of our production cycle, where there’s no plastic in sight, just shiny aluminum in many different shapes.

We chose a premium-grade alloy named ERGAL, renowned for its technical qualities. It’s the ideal material for demanding activities like ski mountaineering because it guarantees reliable performances even in challenging conditions. Being easily machinable, it also allows us to engeneer the extremely precise designs we need to help you achieve performance through lightness.

What’s great about Aluminum is that, once recycled, its technical characteristics remain unchanged, so it can still play the leading role in our process!

In order to achieve a wholly sustainable work environment, we are proudly determined not to scatter potential or used resources.

Since we are resolute in not letting useful and clean resources go right over our heads, we paired the solar panels on our roof with an interesting solution to reduce our energy dependency. An ingenious system of mirrors channels sunlight in an optimal way down multiple skylights, lighting up our warehouse and workshop. Less need for electricity and another reason to enjoy a sunny day!

Here at ATK, we also collect and reuse nearly 97% of our machinery lubricants. The ones that we can't keep in our pants are carefully gathered and disposed of in accordance with our local requirements. Additionally, all processed water is recycled, and the only dispersion occurs through evaporation.

As true Aluminum lovers, we don't shudder if it looks like scrapes, because we know that this alloy has a lot to offer even in the shape of machining chips.

That's why we make an effort to collect and recycle 100% of our production scraps. To achieve this we start by thoroughly separating the aluminum chips from all processed water, which we recover to avoid any dispersion. At this point our pure metal scraps are compacted into chunky disks and are ready to be molted at foundry nearby.

The result? A process easier on the environment, that fully takes advantage of the great qualities of the Ergal Aluminum. Once recycled, in fact, this alloy maintains all its technical characteristics and it’s ready to re-enter our production cycle!